The Classic, Sustainable Choice for Modern Food Packaging– Tin Cans

Tin cans are ideal for packaging food products. The food is preserved, long-life (air tight packaging) and fresh. The nutritive value remains. Tin cans are also easy to transport, also across longer distances.

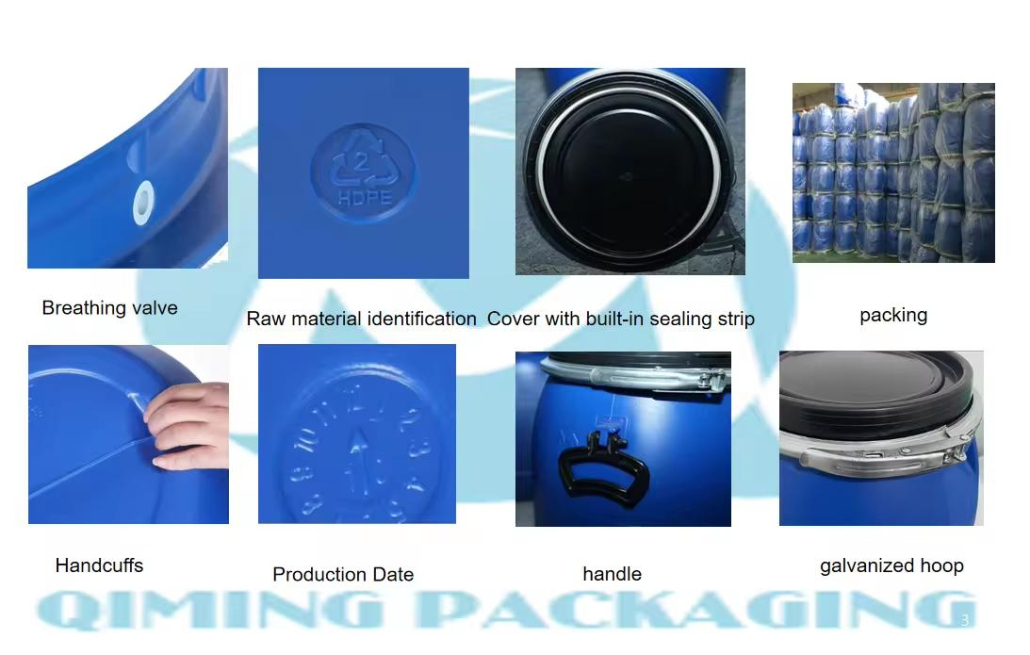

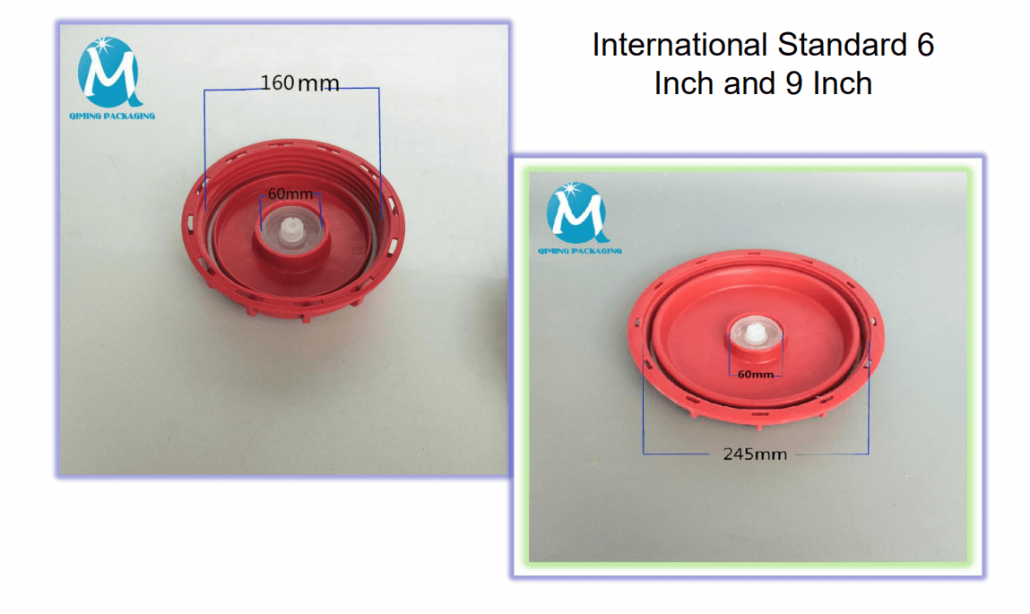

Our tin can packaging meet the demands for food safety and are extremely suitable for high speed filling.In packaging. Cans of tin-plated steel, both those that are permanently sealed and those with tops that can be lifted and replaced, are also used predominantly for food storage. Tin-plate containers are also used to hold paints and varnishes and tobacco, medical, and cosmetic products.

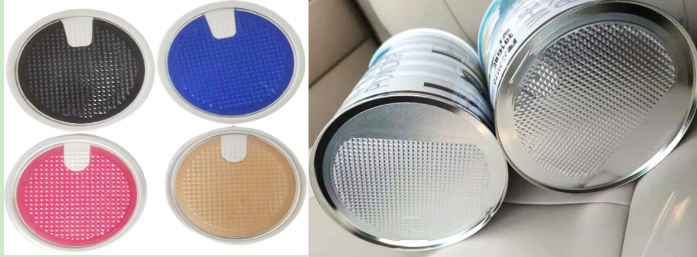

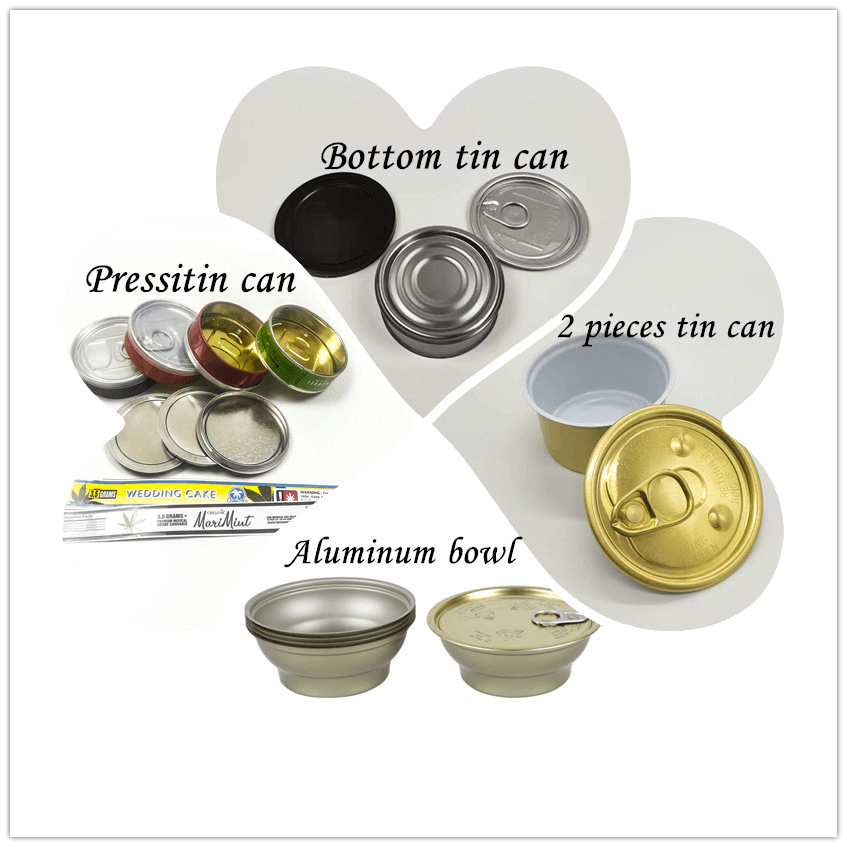

Our food product packaging comes in an array of shapes, sizes, styles, and materials. Protect your food during transportation with our sturdy packaging solutions, designed to keep your products fresh for extended periods. Choose from a range of options such as aluminum cans, cardboard tubes, and tins made of tinplate and aluminium.

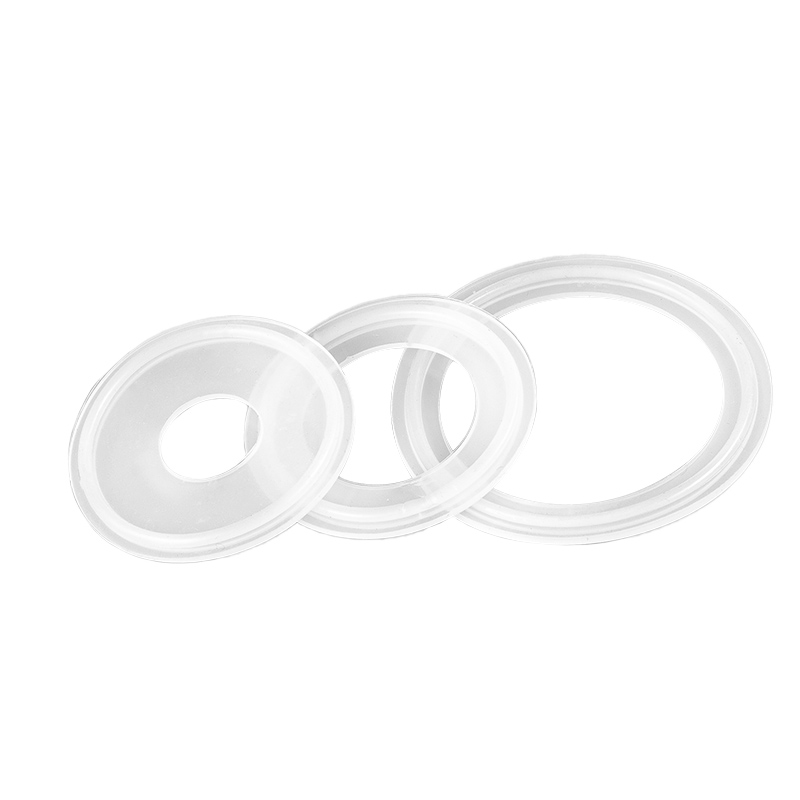

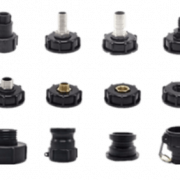

Explore a multitude of features tailored for food items, including window lids, seals that are air-tight or water-tight, and food-safe finishes that maintain the aesthetic appeal of the packaging throughout its use. Find packaging that aligns seamlessly with your product specifications and your brand’s image. With containers of all shapes and sizes, discover the perfect packaging for sweets, beverages, biscuits, and much more.

2 piece empty tuna cans sizes

Logo printing is acceptable. We have been in tin can production area for more than 10 years. Industrial tin cans are available ,too. Like candle tin cans, glue tin cans and paint tin cans. Sealing machine is also available. If you have any interest, feel free to contact us.

Tangshan Qiming Trade Co., Ltd.

known as “Qiming Packaging”, Qiming Packaging is a professional engaged in the research, development, sale and service of packaging and printing products.

Our factory owns professional can making machine and equipment, and has tooled 108 kinds of molds to cater to different customer preferences.

tunna tin can

tunna tin can