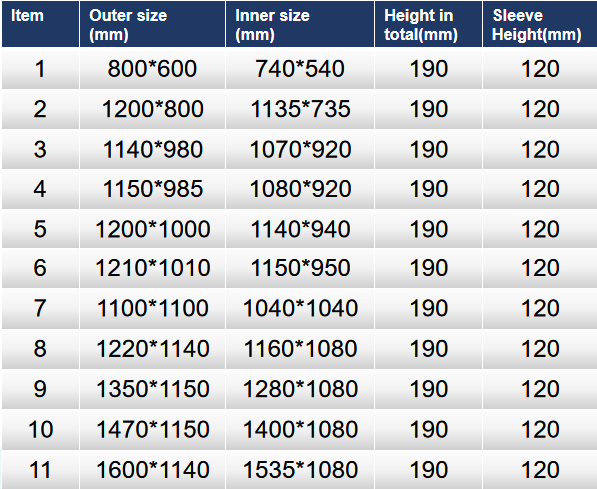

Sleeve Pack Containers

In the realm of logistics and transportation, optimizing space, reducing waste, and enhancing sustainability are paramount objectives. Sleeve Pack Containers (SPCs) emerge as a versatile and innovative solution to address these challenges. With their unique design and functionality, SPCs have revolutionized the way goods are stored, transported, and handled across various industries. This article delves into the features, benefits, and applications of Sleeve Pack Containers, highlighting their pivotal role in modern supply chains.

What are Sleeve Pack Containers?

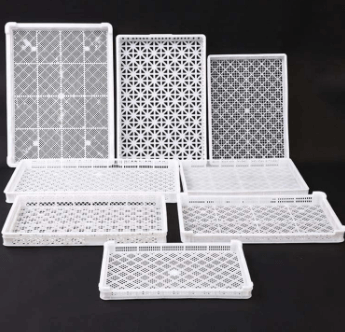

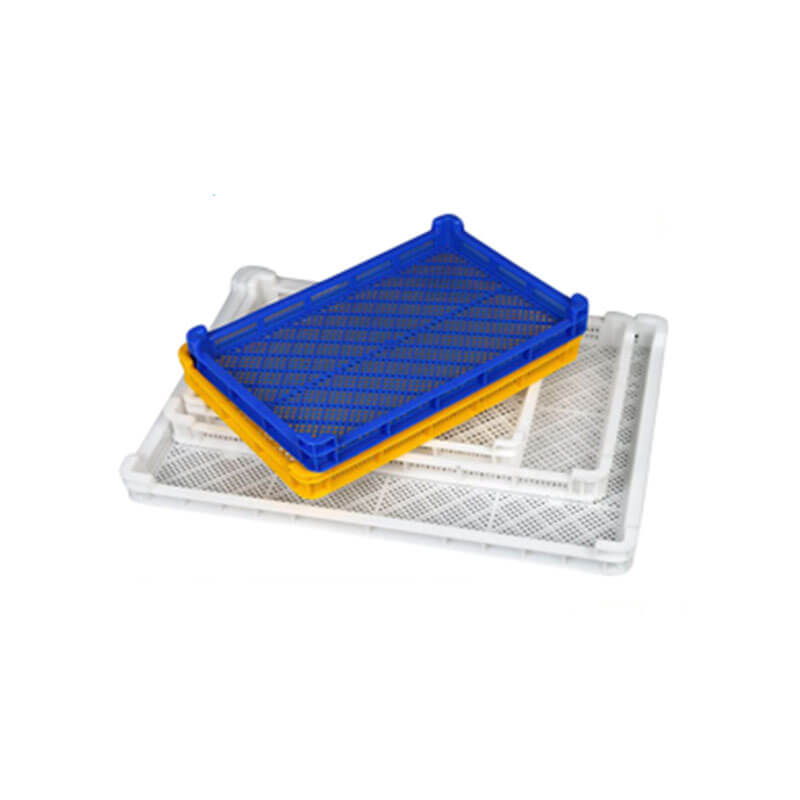

Sleeve Pack Containers, often referred to as collapsible containers or foldable containers, are reusable packaging systems designed to efficiently store and transport goods. They typically consist of a rigid base, collapsible sidewalls, and a detachable sleeve or cover, hence the name “sleeve pack.” This modular design allows SPCs to be easily collapsed when not in use, minimizing storage space and reducing return shipping costs.

Features and Benefits:

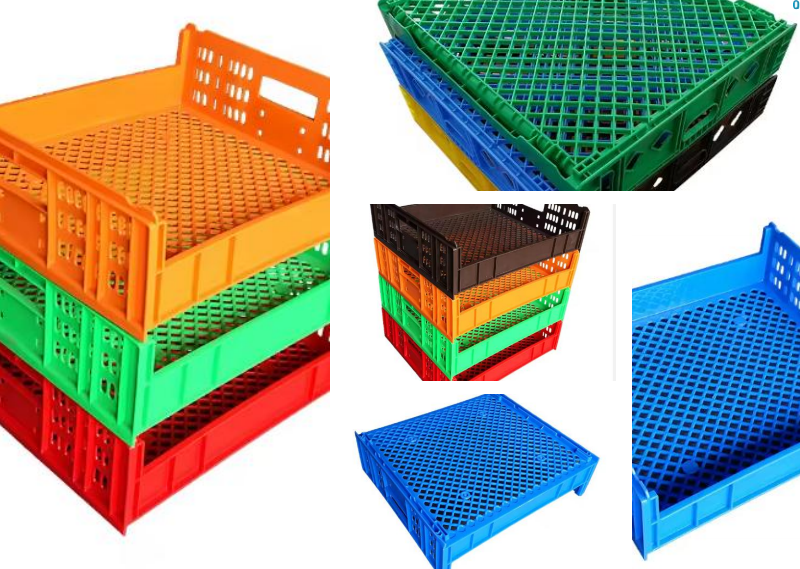

Space Optimization: One of the primary advantages of SPCs is their ability to maximize space utilization. When fully assembled, they provide a sturdy and secure enclosure for goods, safeguarding them during transit. However, their collapsible nature enables them to be folded down to a fraction of their original size, allowing for significant space savings when empty or during return shipments. This feature is particularly advantageous in industries where storage space is limited or costly.

Durability and Reusability: SPCs are constructed from durable materials such as plastic or metal, ensuring longevity and repeated use. Unlike traditional cardboard boxes or wooden crates that may degrade over time, SPCs can withstand the rigors of transportation and handling, resulting in reduced packaging waste and lower lifecycle costs. Additionally, their modular components make them easy to repair or replace, further extending their lifespan and sustainability.

Customization and Versatility: Another key feature of SPCs is their versatility in accommodating various types of goods. They can be customized with dividers, inserts, or foam padding to securely hold fragile items or irregularly shaped products. Additionally, SPCs come in a range of sizes and configurations, allowing businesses to tailor their packaging solutions to specific requirements. Whether transporting automotive parts, electronics, or consumer goods, SPCs offer flexibility and adaptability across diverse industries.

Environmental Sustainability: As sustainability becomes increasingly important in supply chain management, SPCs offer a greener alternative to single-use packaging materials. By promoting reuse and reducing the consumption of cardboard and other disposable materials, SPCs help minimize environmental impact and contribute to a circular economy. Furthermore, their collapsible design reduces the carbon footprint associated with transportation, as fewer trucks are needed to transport empty containers.

Applications:

The versatility of Sleeve Pack Containers makes them suitable for a wide range of applications across various industries:

Automotive: SPCs are commonly used to transport automotive components and parts, protecting during transit while optimizing space in warehouses and distribution centers.

Retail and E-commerce: In the retail sector, SPCs facilitate the efficient handling and storage of merchandise, streamlining logistics operations for both brick-and-mortar stores and online retailers.

Food and Beverage: SPCs can be utilized for the storage and transportation of perishable goods, ensuring freshness and minimizing food waste throughout the supply chain.

Manufacturing: SPCs play a crucial role in the manufacturing process by safely transporting raw materials, work-in-progress inventory, and finished products between production facilities.

Sleeve Pack Containers represent a paradigm shift in packaging and logistics, offering a myriad of benefits including space optimization, durability, customization, and environmental sustainability. As businesses strive to enhance efficiency and reduce costs in their supply chains, SPCs emerge as a versatile solution that aligns with the principles of sustainability and circular economy. By adopting Sleeve Pack Containers, companies can not only streamline their operations but also contribute to a more sustainable future for the planet.

Tangshan Qiming Trade Co., Ltd is a company mainly in Sleeve Pack Containers, plastic crates, plastic baskets, and Stackable

plastic food crates/trays. We have been in this area for more than 10 years. We accept customization and accept urgent orders. If you are interested in our bakery crates, please contact us via finding www.qiminggroup.com. We will answer you within 12 hours.

flange protectors

flange protectors

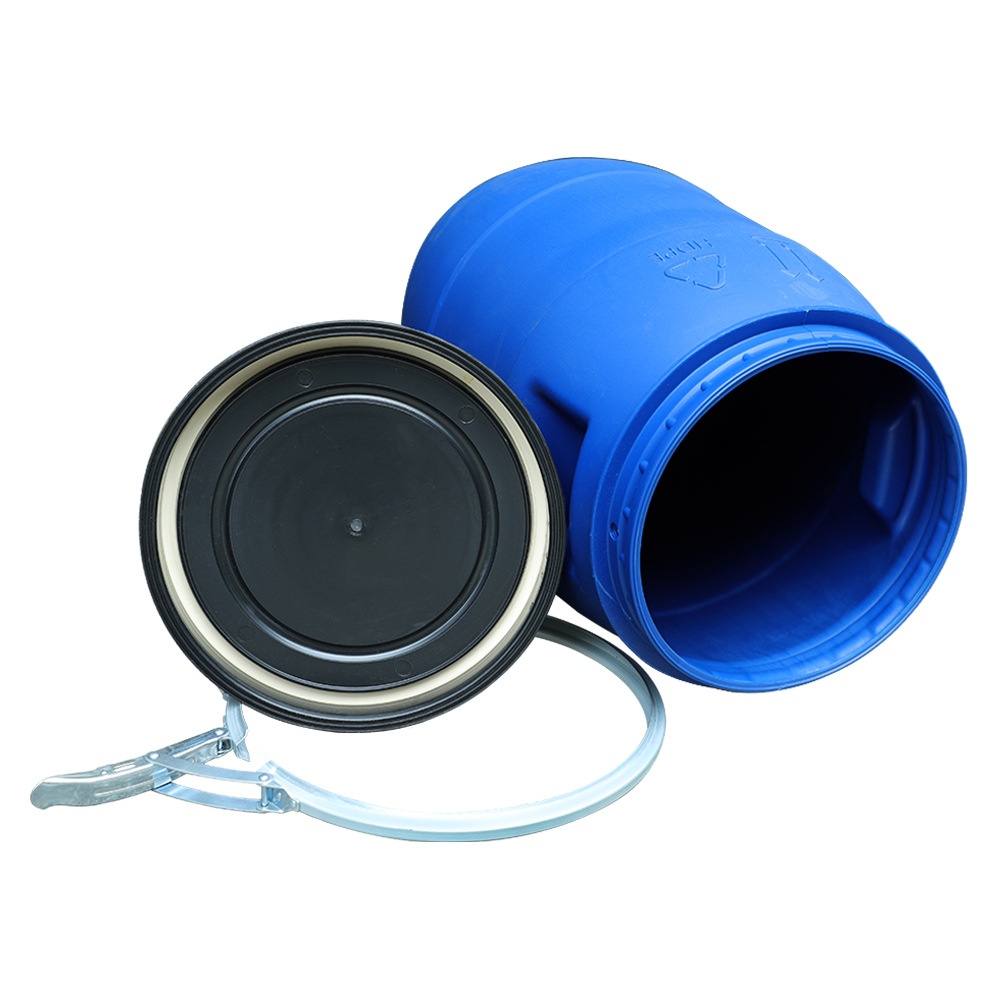

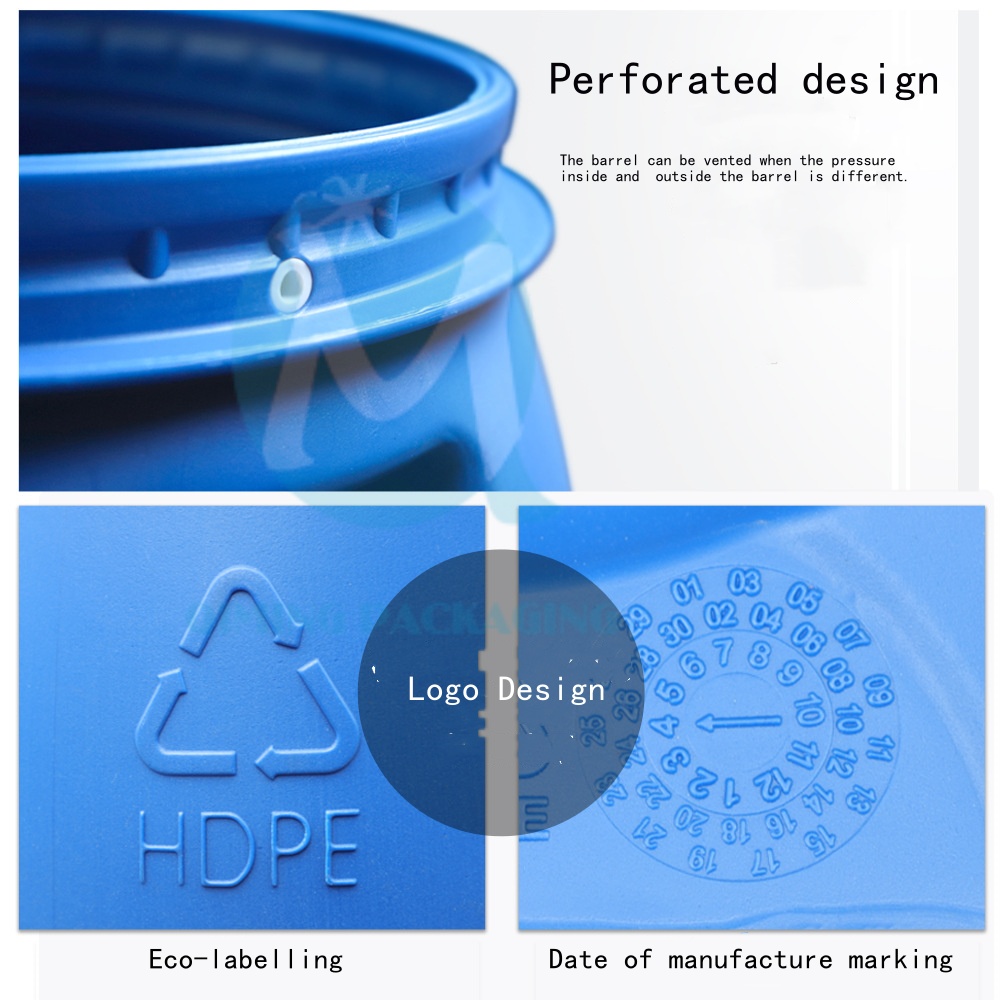

square buckets

square buckets