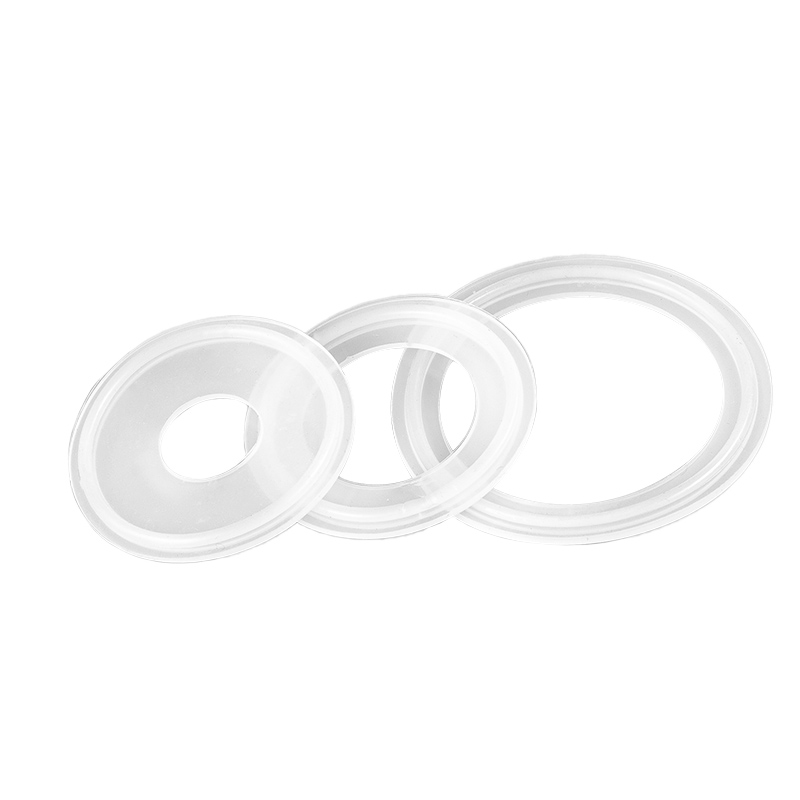

Lid Gasket for IBC Tote Lids

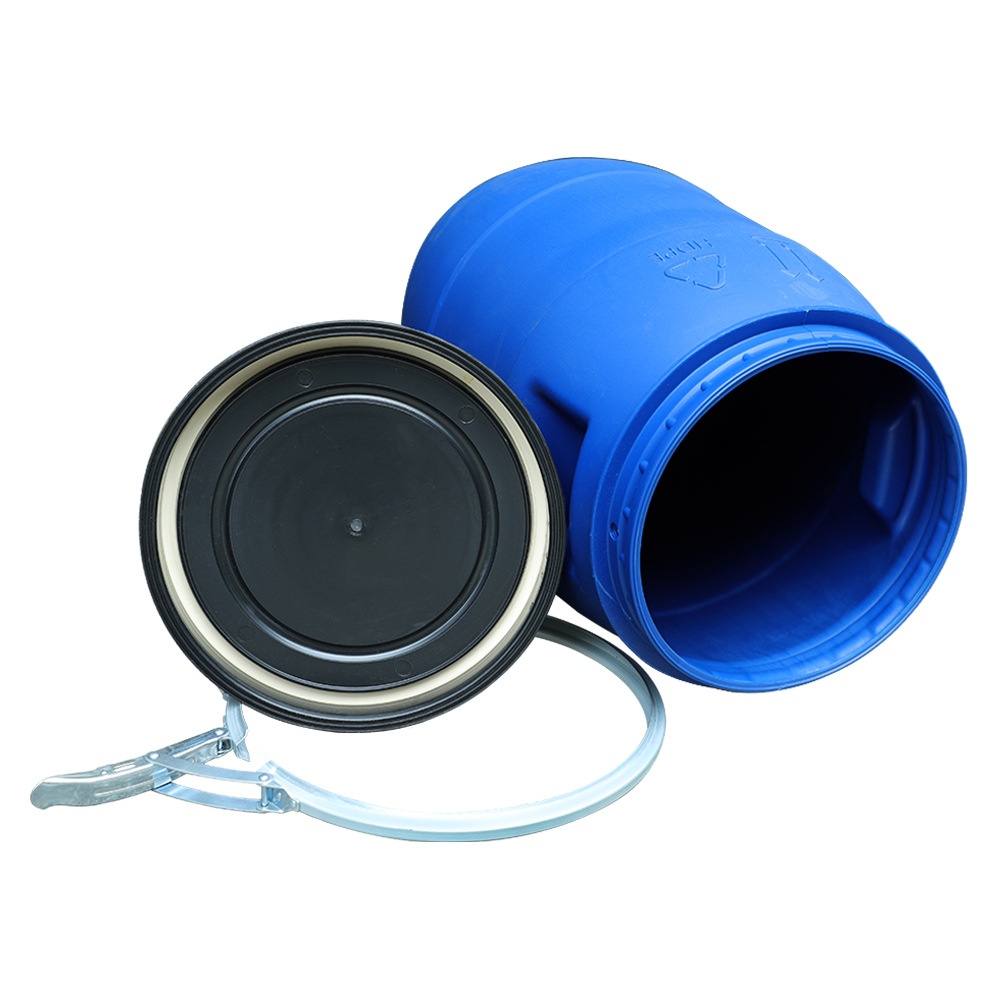

The IBC tank tote is mainly used as the packaging container of chemical raw materials and semi-liquid commodities. It can meet the packaging needs and achieve reasonable packaging effectively.

Keep your IBC tanks leakproof and sanitary with the help of our gaskets! We offer lid gaskets that are suitable for either food or non-food-grade stainless steel or carbon steel tanks, with a variety of different materials available. Shop and compare all our IBC tank and tote accessories!

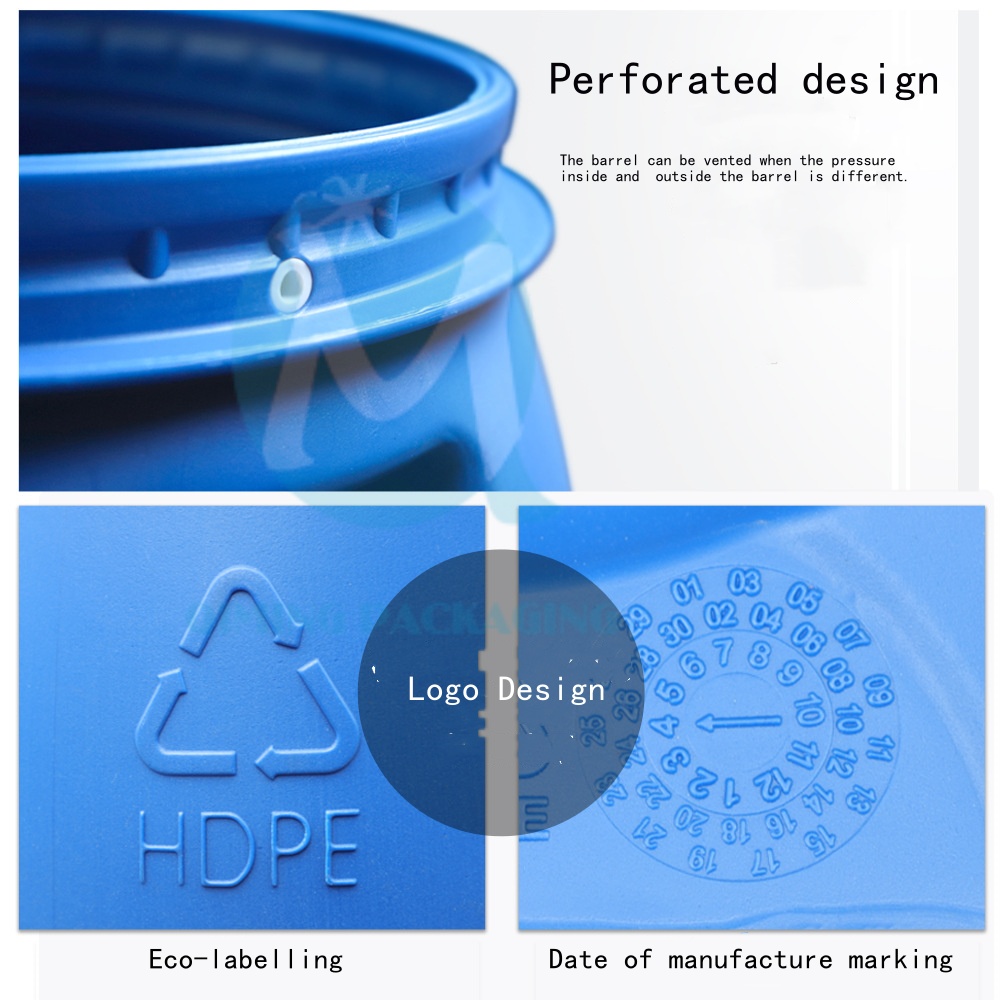

These are all replacement gaskets for IBC tank lids. This 22-1/2″ diameter gasket is made out of durable EPDM which is UV, weather, and abrasion resistant and can be used with a wide variety of different chemicals. It has a 3/4 overlap profile and is a multi-seal design gasket. This gasket is recommended for use with IBC tanks used in non-food grade applications.

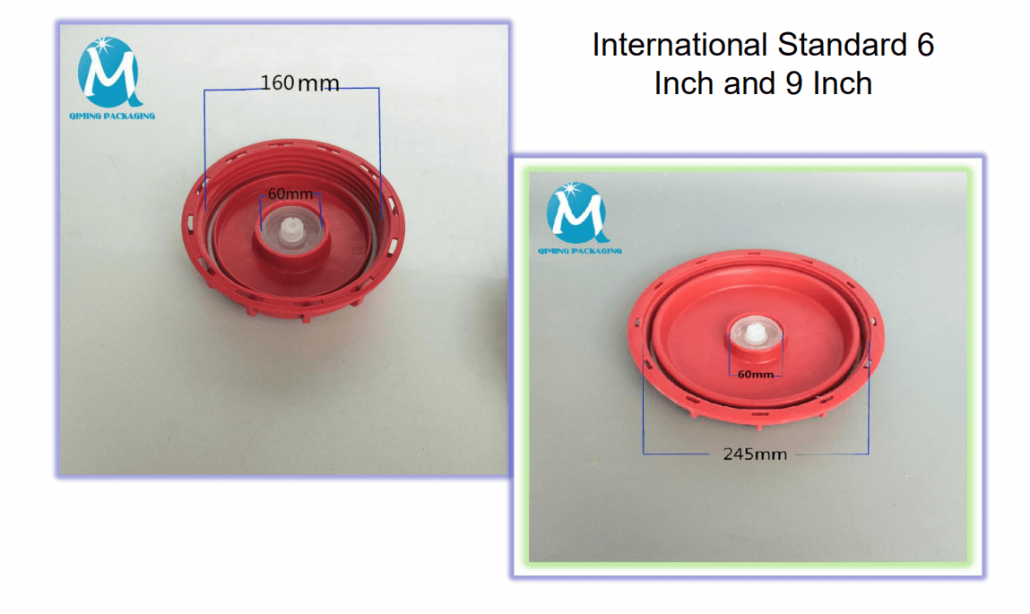

IBC Screw Lids is a necessary part of the tote. We have 6 inches and 9 inches in black, white, and red.

Here are the details of the tank lid. We can accept customized services. It has a fast delivery IBC Tote Lid Cover IBC Tank Lids Water Liquid Storage Plastic Cover Lid Cap Adaptor with Gasket for Chemical Medicine Food and Other Industries Storage. Here are two types: One is a vented type and the other is a non-vented type.

Tangshan Qiming Trade Co., Ltd.

known as “Qiming Packaging”, Qiming Packaging is a professional engaged in the research, development, sale, and service of packaging and printing products.

Our factory owns professional injection equipment and blister equipment and has tooled 108 kinds of molds to cater to different customer preferences.