Plastic engine oil bottle tamper evident cap

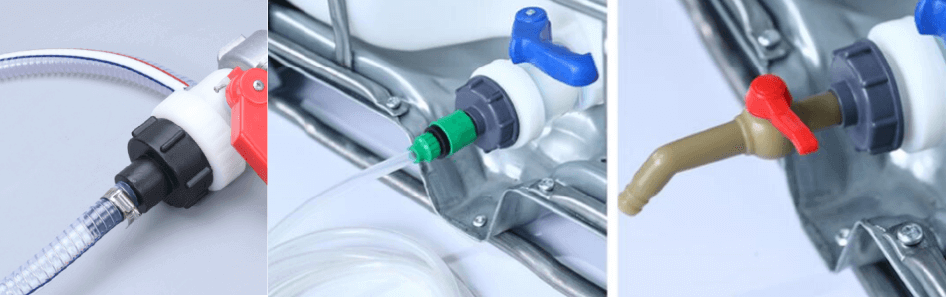

Plastic engine oil bottles are widely used in various fields: lubricants, Motor Oil, Diesel,anti-freezing fluid engine oil, coatings and other engines liquid. Food grade packaging containers, safe and non-toxic, good sealing, anti-pressure drop.

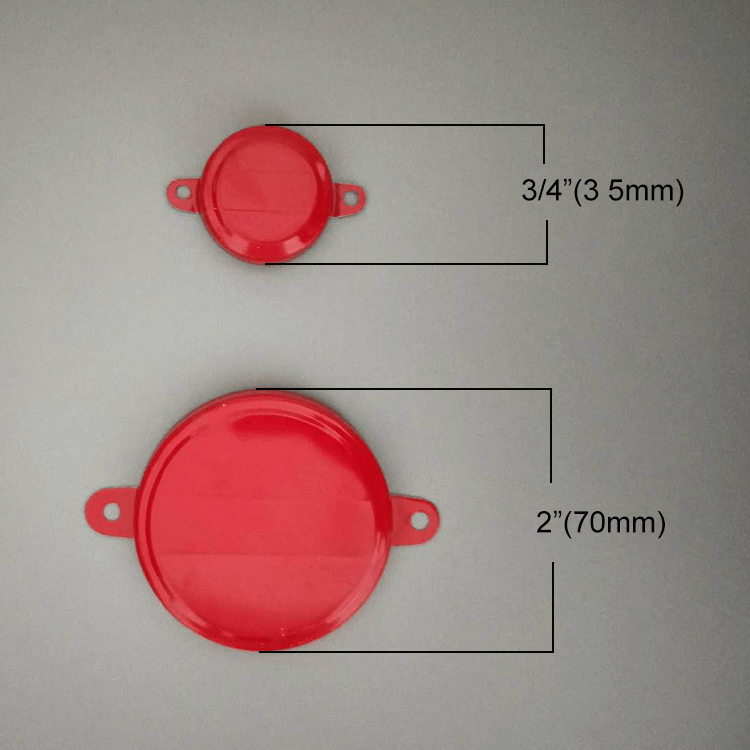

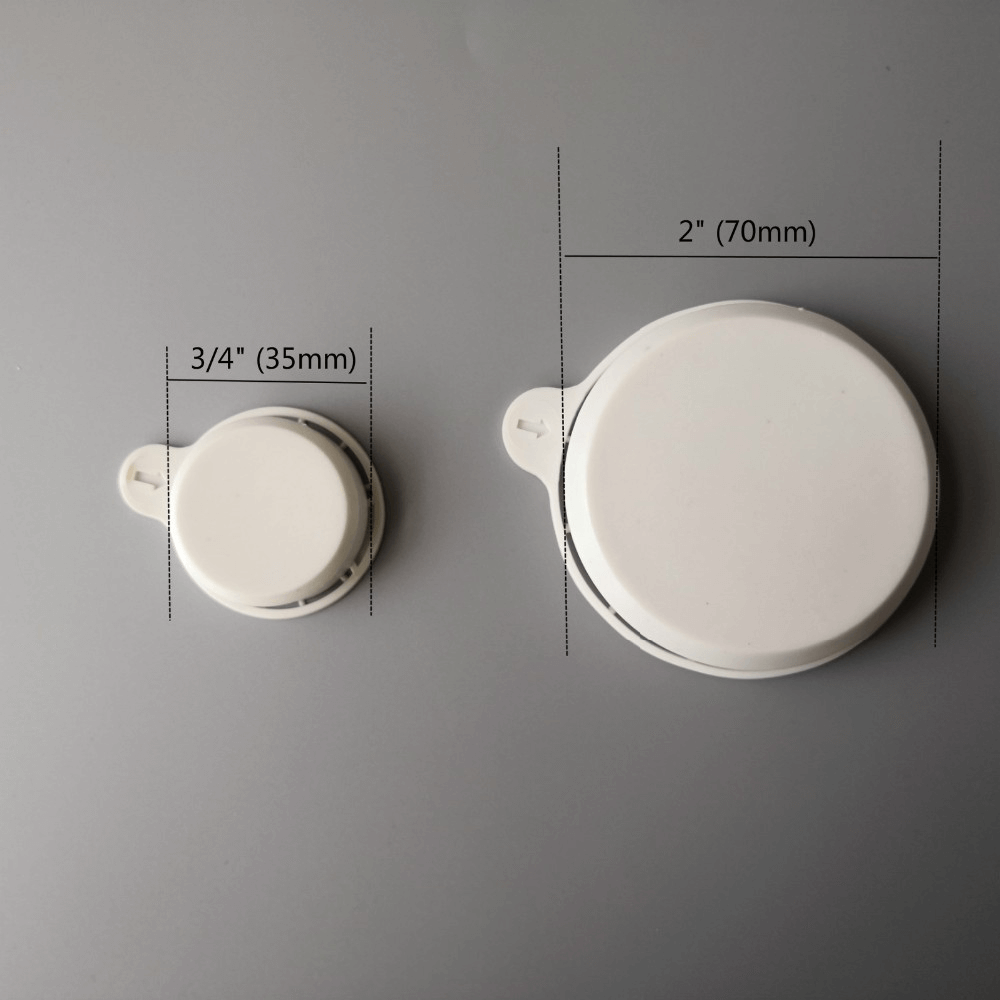

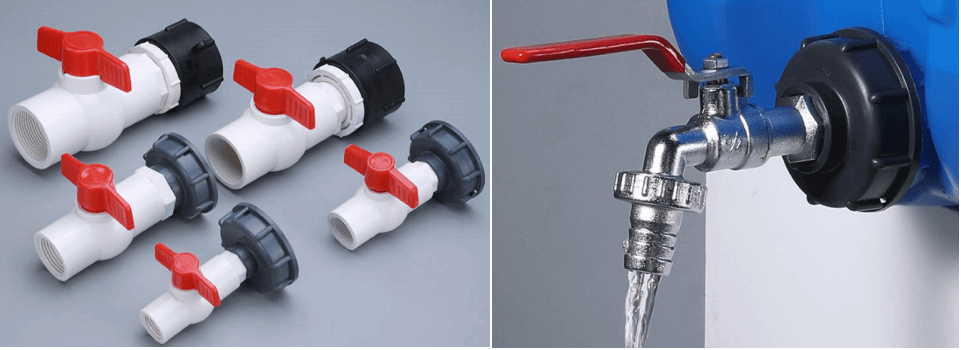

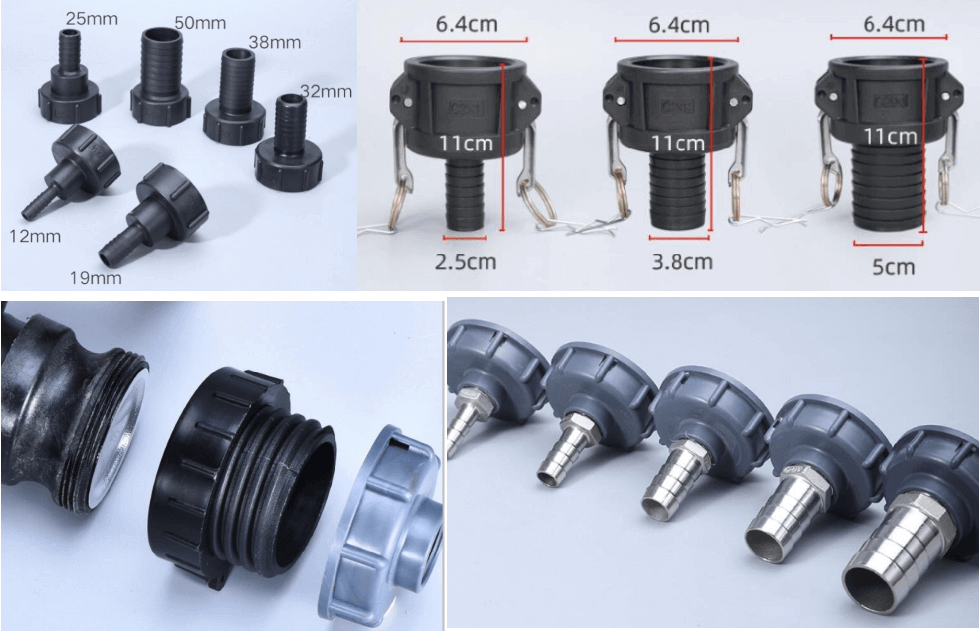

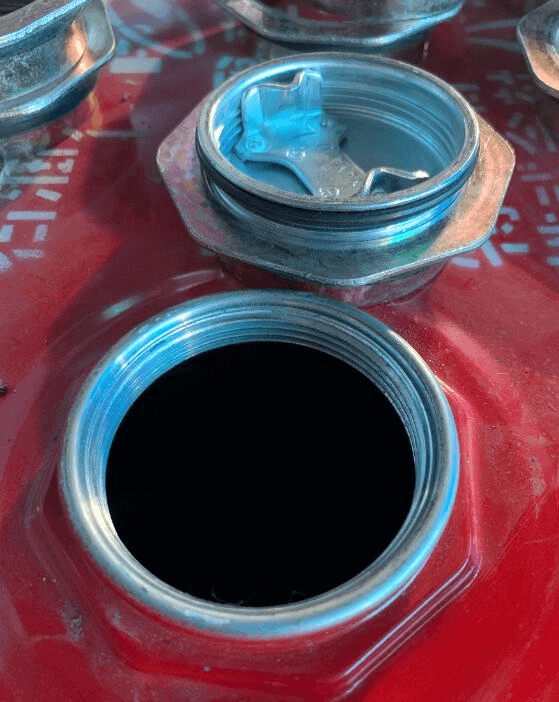

So the Plastic engine oil bottle tamper evident cap is also essential. Generally the diameter of the cap is from 25mm to 60mm for different engine oil bottles.

1.The engine oil bottle caps are PE material, it makes it resistant to corrosion, has good chemical stability, and is resistant to most acids and alkalis (not resistant to acids with oxidizing properties). It is resistant to hydrochloric acid, hydrofluoric acid, phosphoric acid, formic acid, amines, sodium hydroxide at room temperature, Potassium hydroxide and other chemical substances, insoluble in common solvents at room temperature, small water absorption; excellent electrical insulation performance, strong advantages for some oil packaging, anti-static; heat and frost resistance is very good, high temperature can Up to 80 degrees, low temperature minus 40 degrees; the product itself has anti-aging properties, and some products have a service life of more than 20 years.

2.High purity: 100% pure PE raw materials, no impurities, high color, non-toxic, odorless, in line with international standards for oil packaging safety, acceptable third-party testing.

3.The material has high impact strength, wear resistance, light weight, good toughness, shock resistance, drop resistance, compression resistance, absolutely no leakage.

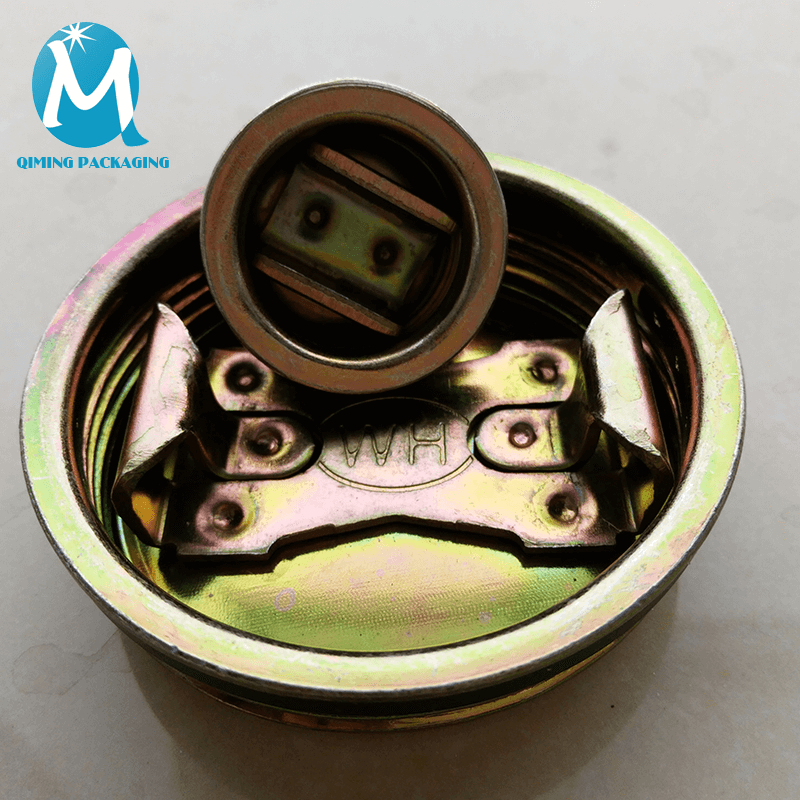

4.Exquisite workmanship and exquisite appearance. The production process adopts the overall one-time molding technology, without seams and leakage. The streamlined appearance is beautiful and not easy to be dirty, and the dirt can be easily removed.

5.The plastic engine oil bottle tamper evident caps are also safe for children, internal sealing gasket, can be easily sealed by the machine.

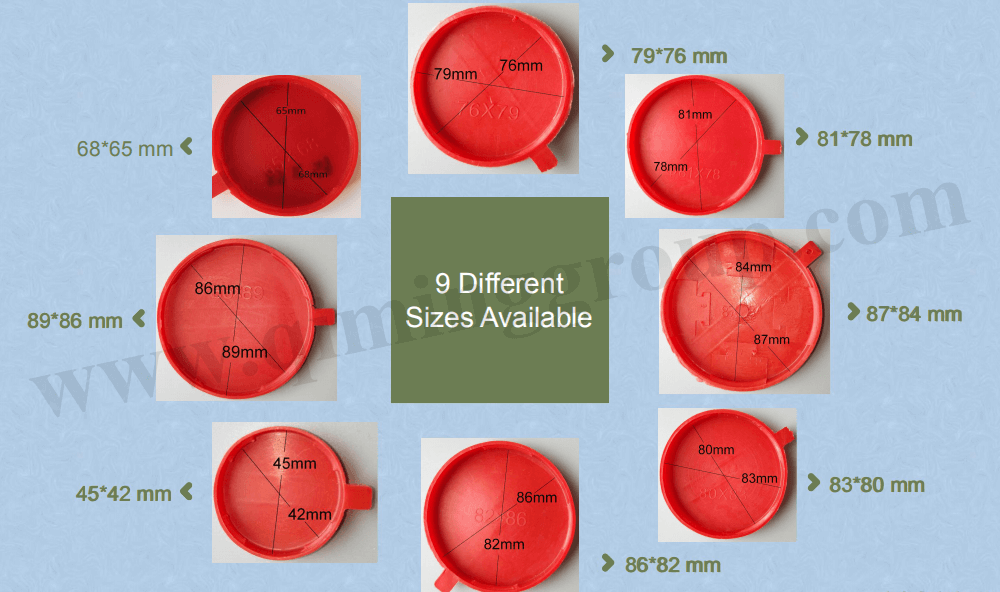

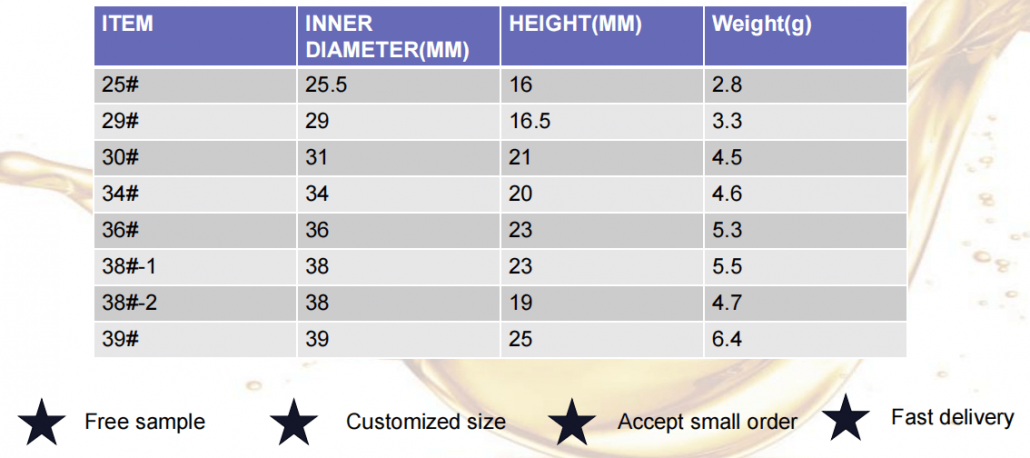

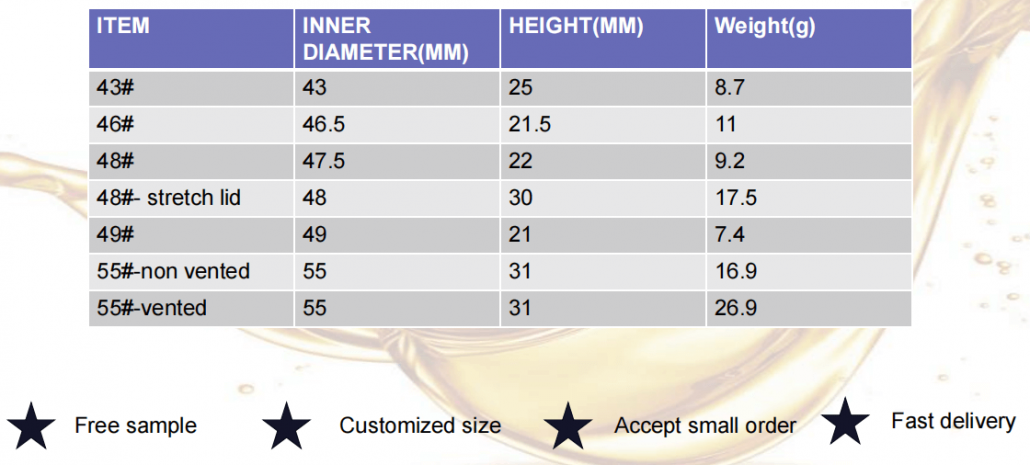

6.The available size list of plastic engine oil bottle caps is here:

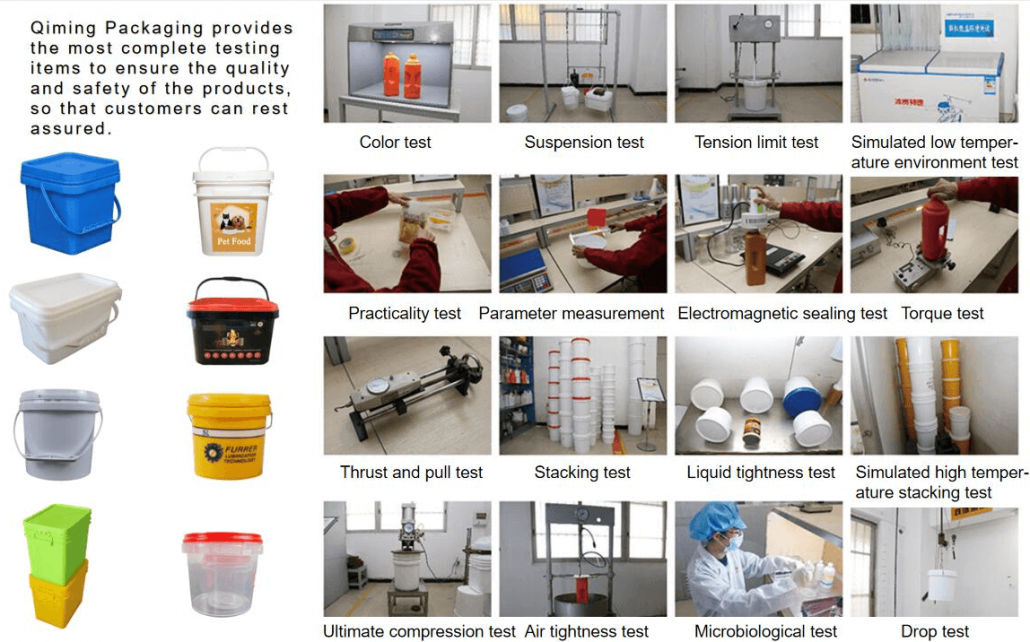

Are you looking for Plastic engine oil bottle tamper evident cap? Qiming Packaging is a professional manufacture specializing in plastic oil bottles, oil caps, buckets, etc. Have special requirement on type or size? Contact us today info@qiminggroup.com for a better solution now. We’ d love to work with you together.

If you do not find the products you want, you can click another website: https://www.qimingpackaging.com/plastic-screw-caps/

Mobile/Whatsapp: 86-15324051286

Company email: mail@qiminggroup.com

Qiming Pack Your More Safety Life!

engine oil bottle caps

engine oil bottle caps

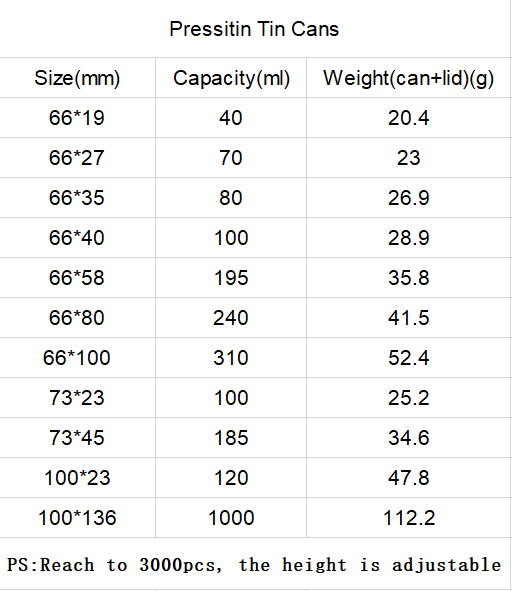

pressitin cans

pressitin cans

empty tin cans

empty tin cans