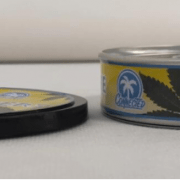

Pressitin body and base

In recent years, the pressitin body and base have become a leader in the canning industry.

Because canned food can better preserve the color, aroma, taste and nutritional value of natural and fresh food. The packaging technology and packaging materials of canned food have attracted much attention due to the fact that the sealing sterilization meets the requirements of commercial sterility and does not need to add preservatives.

It consists of three parts: can body, can base(we call it bottom normally) and plastic top cap. If you want your own logo, then we can provide different stickers.

About the size,now we have size 66*27 mm(diameter*height),66*19 mm,66*35 mm,66*40 mm,66*60 mm,73*20 mm,73*23 mm,73*45 mm in stock.

There are a lot of advantages of our pressitin body and base:

1.Smooth inside and outside surfaces

2. Light weight, high strength, using hard and durable material: tinplate or Tin-free Steel.

3. Smooth inside bottom without welding lines by using deep draw technique.

4. Easy to pour completely.

5.There are many hooks in the bottom.

6.It’s easy to put it in the body,and can’t be take off easily.

7.At last no need the machine seal,just press is okay.

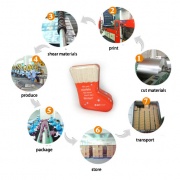

The production process:

iron material-printing-cutting-stamping-assembly-packaging-step by step.

1)Iron:

Generally, after confirming the order, we are going to purchase the iron material, test the quality

2)Printing:

What you should pay attention to in the printing process is to see whether the printing color is keeping up with the model, whether the set is accurate and if there are stain or scratches, etc.

3)Cutting:

After finished the printing, you can cut the material according to the row of cutting beds. When cutting the mattress, pay attention to the operator to see if they cut according to the blade line and whether the length is uniform. Whether the workers scratch each other during unloading, etc., the quality should be checked at the initial operating station.

4)Stamping:

Pressing iron pieces into shapes on a punching machine is the most important work of making a can.

5)Assembly

After the production is completed, the packaging department is responsible for cleaning and assembly, putting in plastic bags and packing. This step is the final work of the production and it is very important, so it must be cleaned before packaging, and then packaged according to the packaging rule. What should be paid attention to in the packaging process is to minimize the inflow of defective products into the finished product, and the quantity of packing must be accurate.

Welcome to your inquiry, please contact us at any time if you are interested in it!